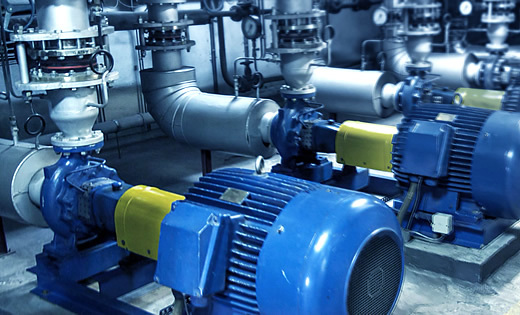

Replacement of mechanical seals for centrifugal pumps

Release time:

2021-09-15

Then install the moving ring on the right side, and inspect the surfaces of the moving and stationary rings to ensure they are clean and free of dirt and rust.

Install the left part first and install it onto the sealing plate.

Then install the moving ring on the right side, and inspect the surfaces of the moving and stationary rings to ensure they are clean and free of dirt and rust.

3. Then install the flat key and impeller again, and install the gasket and nut. Before installation, it is necessary to carefully inspect the number of parts of the mechanical seal to ensure that each part is not damaged, especially the dynamic and static rings, for defects such as bumps, cracks, or deformation. If there are problems, they need to be repaired or replaced with new spare parts.

4. Check the chamfer of the shaft sleeve or gland of the pipeline centrifugal pump to ensure that it is properly installed. If there is any problem, it must be replaced.

"All components of the mechanical seal and their associated assembly contact surfaces need to be cleaned with acetone or anhydrous alcohol before installation. During installation, it is necessary to keep them clean and tidy. In particular, the dynamic and static rings and auxiliary sealing elements should be free of impurities, dust, etc. The surface of the dynamic and static rings needs to be coated with a layer of cleaning oil or turbine oil. Tightening the gland requires aligning the coupling before proceeding,", Bolts need to be tightened to prevent tilting of the gland section. Use a feeler gauge or professional tool to check various points to ensure that all errors do not exceed 0.05 mm

After installation, the moving ring of a centrifugal pump needs to remain flexible in rotation. After pressing the moving ring against the spring, it needs to be ensured that it can bounce back. First, wrap the sealing ring of the stationary ring on the back of the stationary ring, and then install it into the sealing cap end. Pay attention to protecting the end face of the stationary ring, ensuring the perpendicularity of the section of the stationary ring and the center line of the end cap, and align the anti rotation groove on the back of the stationary ring with the anti rotation pin, while ensuring that no collision occurs during installation.

When installing the seal, it is necessary to handle it with care to prevent damage to the seal. When installing a chemical centrifugal pump, it is necessary to ensure that the seal and cavity are cleaned.

Related news

Browse Mobile

Changzhou Sinaer Electric Machinery Co., Ltd

Tel:0086-519-81092688

Fax:0086-519-81090977

Contact: Yu Zhenhai

Mobile phone:0086-13961451821

Add:Aside Lijiafan Shangpu’an Village, Wujin District, Changzhou City, Jiangsu Province, China

copyright © 2023 Changzhou Sinaer Electric Machinery Co., Ltd