"New Generation High Efficiency Motor Test Power Supply" Successfully Developed

Release time:

2021-09-15

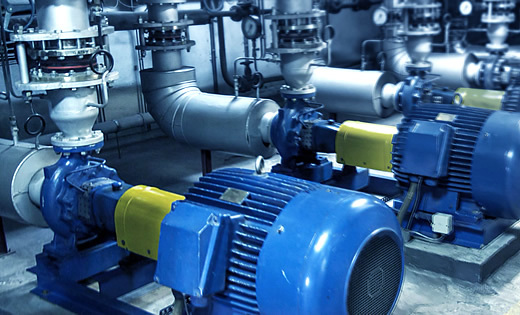

In order to meet the market demand in the field of motor testing, Shandong Xinfengfeng Electronic Technology Development Co., Ltd. has recently developed a "new generation of high-efficiency motor test power supply". The experimental power supply can meet the factory inspection requirements of various types of motors, and has the advantages of environmental protection, energy conservation, multi-purpose, and convenient operation. Its technical indicators reach the advanced level of similar international products.

In order to meet the market demand in the field of motor testing, Shandong Xinfengfeng Electronic Technology Development Co., Ltd. has recently developed a "new generation of high-efficiency motor test power supply". The experimental power supply can meet the factory inspection requirements of various types of motors, and has the advantages of environmental protection, energy conservation, multi-purpose, and convenient operation. Its technical indicators reach the advanced level of similar international products.

According to data, in 2011, the national electric power consumption of electric machines exceeded 2 trillion kilowatt hours. If all high-efficiency electric machines were used, the overall efficiency of the electric machine system could be increased by 3-5%, saving 660-110 billion kilowatt hours of electricity annually, equivalent to the annual power generation of the Three Gorges Power Station.

It is understood that according to China's motor energy efficiency standards, motor energy efficiency is divided into three levels: the first level of energy efficiency is ultra-high efficiency motor, the second level of energy efficiency is high efficiency motor, and the third level of energy efficiency is ordinary motor. According to the size of the motor capacity, there are three modes of motor energy conservation: medium and large motors use system energy conservation methods (including adding frequency converters, etc.), micro motors use DC, frequency conversion, and other technologies, and small and medium-sized motors are mainly used in the industrial field using motor process improvement methods. Taking the most widely used small and medium-sized motors as an example, the current secondary energy efficiency is between 87.5% and 97.5%, while the efficiency of ordinary motors is between 75% and 95%. The efficiency of high-efficiency motors is 1% to 10% higher than that of ordinary motors, which can reduce about 20% to 40% of the power loss.

In order to promote the promotion of high-efficiency motors, the state adopts the "carrot plus stick" policy, combining subsidies with mandatory standards to accelerate the promotion of high-efficiency motors. On June 18, 2010, financial subsidies for high-efficiency motors were started, and the subsidy standard was increased on March 8, 2011; In addition to increasing subsidies, the country has also continuously introduced mandatory policies to enhance the promotion of high-efficiency motors. In 2012, the "12th Five Year Plan" for energy conservation in the industrial system issued by the Ministry of Industry and Information Technology of the People's Republic of China set the growth target of IE2 to be that the entire IE2 motor market will account for more than 80% of the entire motor market by 2015; On April 20, 2012, the Ministry of Industry and Information Technology announced the "Catalogue for the Elimination of High Energy Consumption and Backward Mechanical and Electrical Equipment (Products) (Second Batch)", which includes 135 items in 12 categories of high energy consumption and backward mechanical and electrical equipment. The "GB18613-2006" standard for the entire motor industry stipulates that the motor industry will adopt energy efficiency class II (high-efficiency motors) as a mandatory standard from July 1, 2011. Motors below energy efficiency class II are not allowed to be produced and sold. The country will soon issue a new national standard "GB18613-2012" in September this year, further improving and refining the original standard; The products of the motor manufacturer must pass the test and meet the energy efficiency indicators specified by the state before they can be sold.

With the continuous introduction of various national policies to vigorously promote high-efficiency motors, the desire to promote high-efficiency motors is becoming stronger and stronger, and the implementation efforts are becoming stronger. In the future, more enterprises will choose high-efficiency motors. At that time, the market prospect of high-efficiency motor experimental power supply in the field of motor testing will be broad. Source: Science and Technology Daily

Related news

Browse Mobile

Changzhou Sinaer Electric Machinery Co., Ltd

Tel:0086-519-81092688

Fax:0086-519-81090977

Contact: Yu Zhenhai

Mobile phone:0086-13961451821

Add:Aside Lijiafan Shangpu’an Village, Wujin District, Changzhou City, Jiangsu Province, China

copyright © 2023 Changzhou Sinaer Electric Machinery Co., Ltd